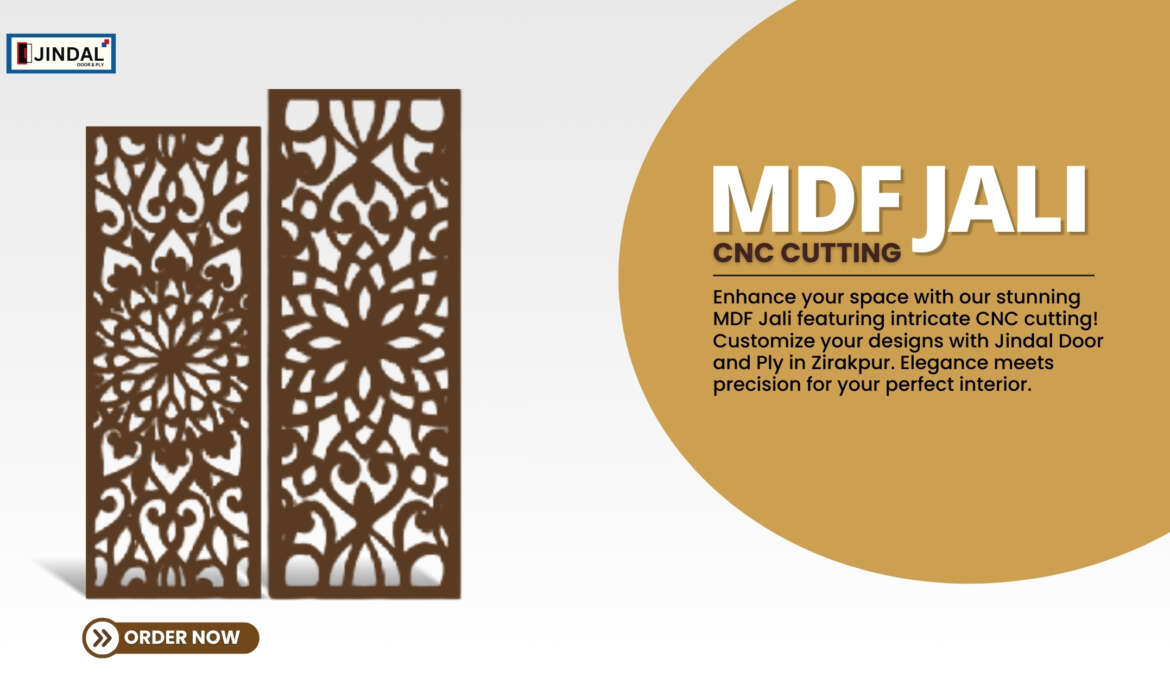

In the vibrant city of Zirakpur, where traditional craftsmanship meets modern innovation, CNC Cutting MDF Jali in Zirakpur has become a popular choice for homeowners and designers. This technology enables the creation of exquisite decorative panels that enhance both the beauty and functionality of any space. In this article, we will explore the advantages of CNC-cut MDF Jali, the technology behind it, and why Jindal Door and Ply is the best option in Zirakpur.

What is CNC Cutting?

CNC stands for Computer Numerical Control. This advanced technology uses computer programming to control cutting machines like routers and lasers. As a result, CNC machines produce highly accurate cuts and intricate patterns that would be difficult to achieve manually. This precision helps artisans design stunning Jali patterns that bring uniqueness and charm to interiors.

Why Choose CNC Cutting MDF Jali in Zirakpur?

There are several reasons why CNC cutting of MDF Jali has gained immense popularity in Zirakpur. First and foremost, CNC technology ensures precision and consistency in every piece, whether it’s a small decorative panel or a large wall divider. Additionally, this method allows for the creation of highly detailed and complex designs that add character to homes and offices.

Moreover, MDF (Medium-Density Fiberboard) is an excellent material for Jali work. It has a smooth surface that paints well, is cost-effective compared to solid wood, and supports sustainable practices since it is made from recycled wood fibers. These features make CNC Cutting MDF Jali in Zirakpur both beautiful and environmentally friendly.

The Benefits of CNC-Cut MDF Jali

1. Stunning Visual Appeal: The intricate lattice patterns created through CNC cutting add elegance and depth to any room. Whether used as wall panels, room dividers, or furniture accents, MDF Jali elevates the overall aesthetic.

2. Improved Ventilation and Light Control: One key benefit of Jali designs is their ability to allow natural airflow and light while maintaining privacy. This is especially useful in the warm climate of Zirakpur.

3. Durability: Thanks to the high-quality MDF used by Jindal Door and Ply, these Jali panels offer long-lasting strength and resistance to wear and tear.

Jindal Door and Ply: The Best in CNC Cutting MDF Jali in Zirakpur

Jindal Door and Ply has built a reputation for delivering superior craftsmanship combined with modern technology. Their team of skilled artisans works closely with clients to create customized Jali designs that perfectly match their vision and space requirements.

Additionally, Jindal offers a wide range of design options, from traditional motifs to contemporary styles. This flexibility ensures that every customer finds a design that complements their décor beautifully.

Applications of CNC Cutting MDF Jali in Zirakpur

CNC-cut MDF Jali is incredibly versatile. You can use it in:

- Decorative Wall Panels: Create eye-catching feature walls.

- Room Dividers: Separate spaces without blocking light or airflow.

- Furniture Accents: Add unique designs to cabinets, tables, and doors.

- Acoustic Panels: Help reduce sound reflections in large rooms.

Maintenance and Installation

For optimal results, Jindal Door and Ply provide professional installation services. They ensure each panel fits perfectly and functions well. Regular cleaning and occasional touch-ups keep your MDF Jali panels looking fresh and elegant for years.

Conclusion

To sum up, CNC Cutting MDF Jali in Zirakpur offers a perfect blend of tradition and technology. This technique allows you to add artistic charm, durability, and functionality to your spaces. With Jindal Door and Ply, you can trust in expert craftsmanship, customizable designs, and premium-quality materials.

If you want to transform your interiors with stylish and durable Jali panels, look no further than Jindal Door and Ply in Zirakpur. Embrace the beauty of CNC-cut MDF Jali and make your home truly stand out.